Deciding between in-person and online forklift training is a big deal for people looking to drive forklifts, whether they’re just starting out or have been at it for a while.

This choice affects how well they learn to safely and efficiently operate a forklift. In our deep dive, we’ll look at both options from all angles—what makes each great, what might hold you back, and everything in between.

Whether it’s the hands-on experience and face-to-face instruction of in-person training or the flexibility and cost savings of learning online, we’re here to help you figure out the best fit for your forklift driving journey.

In-Person Forklift Training

In-person forklift training is like learning to ride a bike with someone right there to guide you. You go to a place where they have forklifts and teach you how to use them step by step. This way of learning has been around for a long time because it’s a hands-on job, and the best way to learn is by actually doing it.

What’s Great About It?

- Real Practice: You get to drive a forklift for real, not just in videos or simulations. It’s like learning to swim in water instead of reading about it.

- Help Right Away: If you’re doing something wrong or just don’t get it, an instructor is there to show you how to do it right then and there.

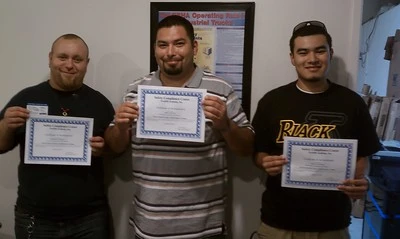

- Learning Together: It’s more fun and you can learn a lot from being around other people who are learning too. You can ask questions, see how others do things, and get tips from them as well.

But, It’s Not Perfect

- Costs More: Because they need real forklifts and a place to use them, and because instructors spend time with you, it can be pricier. Think of it like paying for personal training at a gym instead of just watching workout videos at home. The cost of taking the in-person is somewhere around $150-$450 depending on the type of forklift you want to take the training on and the comprehensiveness of the course.

- Scheduling Can Be Tough: You have to show up when the training is scheduled, and if the training center isn’t close by, getting there can be a hassle. It’s like having a class at school that you can’t miss but it only happens at one specific time.

- Not a Lot of Room: There’s only so much space and so many forklifts, so classes can’t be too big. This means spots can fill up fast, kind of like trying to get tickets to a concert of a really popular band.

The in-person forklift training gives you the real deal in learning how to operate a forklift, with experts guiding you every step of the way in a group setting. But, it might be a bit on the pricey side, require traveling, and finding a spot can sometimes feel like snagging a seat at a crowded cafe.

Online Forklift Training

Online forklift training is a modern way to learn how to safely operate forklifts without having to be in a specific place at a specific time for class. This kind of training has gotten more popular, especially since it’s easy to fit into busy schedules and can be done from anywhere, even from your own home.

Advantages:

- Flexibility: You can pick when and where you study. Whether it’s early morning before work or late at night, you’re in control.

- Cost-effective: Generally, learning online costs less than traditional classes. You save on travel expenses, and course fees are often lower because there’s no need for physical classroom space or equipment. The cost of online training is somewhere around $75-$120 which is much cheaper compared to in-person.

- Accessible to everyone: It doesn’t matter where you live, even if it’s far from the nearest training center. As long as you have internet, you can take these courses. You can take it on your PC at home or on mobile phone in your hand.

Challenges:

- No real-life practice: The biggest downside is you don’t get to actually drive a forklift or practice with real equipment, which is crucial for this kind of job.

- Staying focused: Without a teacher and classmates around, some might find it hard to stay engaged or understand complex topics alone.

- Certification concerns: Some employers or laws might not recognize online certificates the same way they do for in-person training, questioning if an online-only trained operator is truly ready.

Online forklift training offers convenience and savings but lacks the hands-on experience that can be critical for safely operating a forklift. It’s great for theory and learning the rules, but you might need to find other ways to get actual driving practice.

Comparing the Two (2) Methods

When choosing between in-person and online forklift training, it’s important to weigh several factors to see which method aligns best with your needs. Let’s break down these key areas:

Effectiveness

Studies and experts often debate which training style learners absorb better. In-person training usually wins points for its direct, hands-on approach, helping learners get a real feel for the equipment. This can be crucial for building confidence and competence in operating a forklift safely. Online training, on the other hand, is praised for its comprehensive theoretical knowledge and convenience, but the lack of physical practice might leave some learners feeling less prepared for real-world forklift operation.

Cost

Money matters, and here’s where the difference gets interesting. In-person training can be more expensive, sometimes costing hundreds to a few thousand dollars, because it requires physical equipment, space, and instructors’ time. Online training often slashes these costs, offering courses that range from significantly cheaper to even free, making it a budget-friendly option for many.

Accessibility

Online training shines in its accessibility. As long as you have an internet connection, you can learn from anywhere, anytime. This is a game-changer for people living far from training centers or with tight schedules. In-person training, while less flexible, provides an immersive environment that might benefit learners who thrive under direct supervision and structure.

Certification and Recognition

The acceptance of online vs. in-person certifications can vary widely across industries and regions. Some employers and regulatory bodies might require hands-on assessments, making in-person training a must. However, online training certifications are increasingly recognized, especially when they’re complemented by practical evaluations or recognized by reputable organizations.

Hands-On Experience

Finally, the essence of forklift operation lies in the actual driving and handling of the machinery. In-person training offers undeniable value by allowing learners to experience the forklift’s weight, controls, and how it moves and reacts. Online training tries to compensate with simulations and videos, but it can’t fully replicate the experience of maneuvering a forklift through tight spaces or lifting loads in a safe, controlled environment.

In summary, your choice between in-person and online forklift training might hinge on what you prioritize: the thoroughness of hands-on experience, the convenience and cost of online learning, or the specific requirements of your job or industry. Each method has its strengths and challenges, so consider your situation, goals, and how you learn best before making a decision.

How to Decide Between The Two Methods

Deciding between in-person and online forklift training involves weighing several factors based on your personal circumstances, goals, and preferences. Here’s a straightforward guide to help you make the best choice:

1. Assess Your Learning Style

- Hands-on Learner: If you grasp concepts better by doing, in-person training with its direct access to forklifts might be more beneficial.

- Theory and Flexibility: If you prefer to learn at your own pace or need to fit training into a busy schedule, online courses could be the answer.

2. Consider Your Budget

- In-person training can be pricey due to the costs associated with physical resources and expert instructors. If funds are tight, online training offers a more affordable route.

3. Evaluate Your Access to Training Locations

- If you live far from training centers, the travel time and costs could add up. Online training eliminates this hurdle, allowing you to learn from anywhere.

4. Check Certification Requirements

- Some jobs or regions have strict requirements regarding forklift certification. Investigate whether online certifications are accepted or if an in-person course is necessary for the credentials you need.

5. Reflect on the Importance of Hands-on Experience

- Operating a forklift safely requires more than theoretical knowledge. If gaining actual driving experience is important to you, in-person training is likely the better option.

6. Understand Your Career Goals

- If you’re aiming for a position in a highly regulated industry or with an employer known for stringent safety standards, the comprehensive approach of in-person training might be more aligned with your career trajectory.

7. Look for Hybrid Options

- Some programs offer a combination of online theoretical learning and in-person practical training. This hybrid model can provide the best of both worlds if you’re undecided.

Making the Decision

After considering these factors, reflect on which aspects are non-negotiables for you and which ones you’re flexible about. If you still find it challenging to decide, seek advice from professionals in the field or talk to training providers about your concerns. They might offer insights or solutions you hadn’t considered. Ultimately, the right choice is the one that best aligns with your learning style, meets your needs for certification and practical experience, and fits your personal circumstances.

When Deciding, You Need to Consider What OSHA Requires

When deciding between in-person and online forklift training, it’s crucial to consider the Occupational Safety and Health Administration (OSHA) requirements, which are detailed in OSHA regulation 29 CFR 1910.178(l). This regulation outlines the training requirements for forklift operators to ensure they can operate forklifts safely and effectively.

Key Aspects of OSHA Regulation 29 CFR 1910.178(l):

- Training Program Implementation: Employers must implement a training program based on the general principles of safe truck operation, the types of vehicles being used in the workplace, the hazards of the workplace created by the use of the vehicles, and the general safety requirements of the OSHA standard.

- Training and Evaluation: The regulation specifies that operators must receive initial training in topics relevant to safe forklift operation and must be evaluated on their performance. This includes practical training (demonstrations performed by the trainer and practical exercises performed by the trainee) and an evaluation of the operator’s performance in the workplace.

- Certification: Upon completion of training and evaluation, the employer must certify that each operator has been trained and evaluated in accordance with OSHA standards. This certification must include the operator’s name, the training date, and the evaluator’s name.

- Refresher Training and Evaluation: Operators must undergo additional training in certain situations, such as when they are involved in an accident or near-miss incident, when they have been observed operating the vehicle in an unsafe manner, when they are assigned to a different type of truck, or when a condition in the workplace changes in a manner that could affect safe operation of the truck.

Considerations Based on OSHA Requirements

- Certification Validity: If opting for online training, ensure the program includes or allows for a practical evaluation to meet OSHA’s certification standards. Simply completing an online course without demonstrating practical competency may not suffice for OSHA compliance.

- Choosing In-Person Training: Given the emphasis on practical skills and evaluations, in-person training programs are inherently aligned with OSHA requirements. These programs typically offer comprehensive hands-on training experiences that meet or exceed OSHA standards.

- Blended Learning Options: Some training providers offer blended learning options that combine the flexibility of online theoretical instruction with the practicality of in-person hands-on training. This approach can satisfy both the convenience of online learning and OSHA’s requirements for practical competency.

- Employer Responsibilities: Remember, employers are ultimately responsible for ensuring their forklift operators are properly trained and evaluated according to OSHA standards. If you’re an employer, consider the structure of the training program and its ability to comply with OSHA requirements fully.

Final Thoughts

Before making a decision, verify whether the training program—be it in-person, online, or blended—meets OSHA standards and includes a provision for practical evaluation. Whether you’re an individual seeking certification or an employer looking to train your staff, compliance with OSHA’s requirements is non-negotiable for both legal compliance and the safety of all involved.

To Make a Conclusion

Choosing the right forklift training method, whether in-person or online, is a crucial decision that impacts not only compliance with OSHA regulations but also the safety and efficiency of operations. In-person training offers the invaluable benefit of hands-on experience and direct feedback, aligning closely with OSHA’s emphasis on practical skills.

On the other hand, online training provides flexibility and accessibility, appealing to those who need to balance training with other commitments or who prefer self-paced learning.

However, it’s essential to ensure that any online program is complemented by opportunities for practical application to meet OSHA’s comprehensive standards. Ultimately, the decision should be guided by a careful consideration of learning styles, budget constraints, certification requirements, and the need for practical, real-world experience.

By prioritizing safety and compliance, individuals and employers can select the training path that best prepares operators for the demands of safe and effective forklift operation.